Also known as touch keyboard, it adopts an integral sealed structure composed of a flat multi-layer combination. It is a new type of electronic component that integrates light, machine and electricity, and seals the key switch, panel, mark, symbol display and lining together. It is a fundamental change in the appearance structure of electronic products. It can replace the keys of conventional discrete components and perform the tasks of the operating system more reliably. Membrane switches have good waterproof, dustproof, oil-proof, and anti-corrosion of harmful gases. The performance is stable and reliable, light weight, small size, long life, easy assembly, the panel can be washed without damage to the characters, rich colors, and beautiful appearance. Using membrane switches makes your products more contemporary. Main types of membrane switches The membrane switch panel is an electronic component that integrates switch functions and decorative functions, consisting of a rigid or flexible printed circuit board as the base, with buttons with or without feel installed, and then covered with a plastic (polycarbonate PC, polyester PET, etc.) film panel printed with colorful decorative patterns. It is a new type of human-computer dialogue interface. The connection between its switch circuit and the whole machine can be completed by welding or plugging.On the other hand, silicone rubber keyboard It also brings tangible benefits to everyone and feels useful. It is a model of the industry. https://singway-touch.com/

membrane switch types

Types of membrane switches

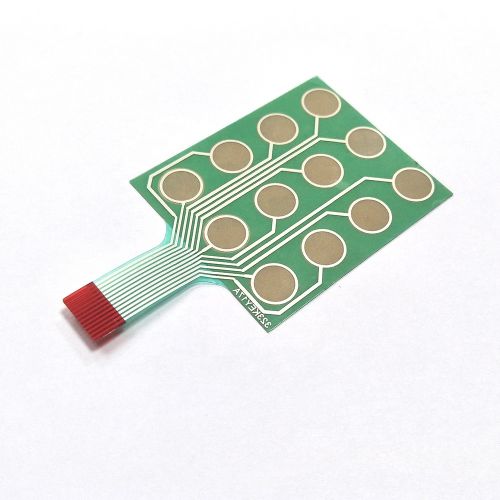

1. Flexible membrane switch

Flexible membrane switch is a typical form of membrane switch. This type of membrane switch is called flexible because the mask layer, isolation layer, and circuit layer of the membrane switch are all composed of flexible films of various properties. The circuit layer of the flexible membrane switch uses polyester film (PET) with good electrical properties as the carrier of the switch circuit pattern. This layer is also divided into hand-feel springs and upper and lower circuits. Due to the properties of polyester film, the membrane switch has good insulation, heat resistance, folding resistance and high resilience. The graphics of the switch circuit, including the switch connection and its lead wires, are printed with low-resistance, low-temperature cured conductive paint. Therefore, the composition of the entire membrane switch has a certain degree of softness, which is not only suitable for use on flat bodies, but also can be used with curved bodies. The lead wires of the flexible membrane switch are integrated with the switch body. When making the connection of the group switch, they are gathered at a certain place on the membrane and extended outward according to the position specified in the design and the standard line spacing. They are connected to the rear circuit of the whole machine as soft, arbitrarily bendable and sealed lead wires.

membrane switch types

2. Rigid membrane switch

Rigid membrane switch refers to a switch whose graphics and circuits are made on a common printed circuit copper-clad board. The characteristics of rigid membrane switch are convenient material acquisition, stable process, low resistance, and certain components in the circuit can be directly welded on its back. In the case of a small area, the rigid lining layer can be omitted. Rigid membrane switches generally use metal guides as the contact points for conducting the labyrinth, so they have a better feel. The disadvantage is that they are not as convenient to install in the whole machine as soft membrane switches, and often require welding and lead-out through flat cables. In addition to buzzer signals and LED indications, the information feedback of rigid membrane switches generally uses metal feel springs.

membrane switch types

3. Flat membrane switch

The buttons on the membrane switch use different colors to indicate the position, shape and size of the key body, which is more common in the initial stage of membrane switches. Three-dimensional membrane switch: Usually, the buttons on the membrane switch only use colors to express the position, shape and size of the key body. In this way, the accuracy of the operation can only be identified by the operator’s vision. Since there is no appropriate feedback information to indicate whether the finger is pressed within the effective range of the switch to make the switch operate, it affects the confidence in monitoring the entire machine and the speed of operation. A membrane switch that makes the switch key body slightly raised and slightly higher than the panel to form a three-dimensional shape is called a three-dimensional key switch. The three-dimensional key can not only accurately give the range of the key body, improve the recognition speed, and make the operator’s sense of touch more sensitive, but also enhance the decorative effect of the product appearance. The production of three-dimensional keys.