In the world of computer hardware, efficient data transfer and storage are paramount. One of the key components facilitating this process is the SATA (Serial ATA) hard drive data cable. This blog post delves into the significance, types, and applications of SATA hard drive data cables in modern computing.Hope for the future electrical terminal connectors It can achieve rapid and stable development and serve social development and people’s needs well. https://www.xpbdz.com/

What is a SATA Hard Drive Data Cable?

SATA hard drive data cables are essential for connecting storage devices like hard drives and SSDs (Solid State Drives) to the motherboard. Introduced in the early 2000s, SATA technology replaced the older PATA (Parallel ATA) system, offering faster data transfer rates and improved overall performance.

Key Features and Benefits

1.High Data Transfer Rates: SATA cables support data transfer rates ranging from 1.5 Gbps to 6 Gbps, depending on the version (SATA I, II, or III). This ensures swift and efficient data access and storage.

2.Slim and Flexible Design: Unlike bulky PATA cables, SATA cables are thin and flexible, promoting better airflow within the computer case and reducing cable clutter.

3.Hot Swapping: SATA technology supports hot swapping, allowing users to connect and disconnect drives without powering down the system. This feature is particularly useful for server environments and systems requiring frequent hardware changes.

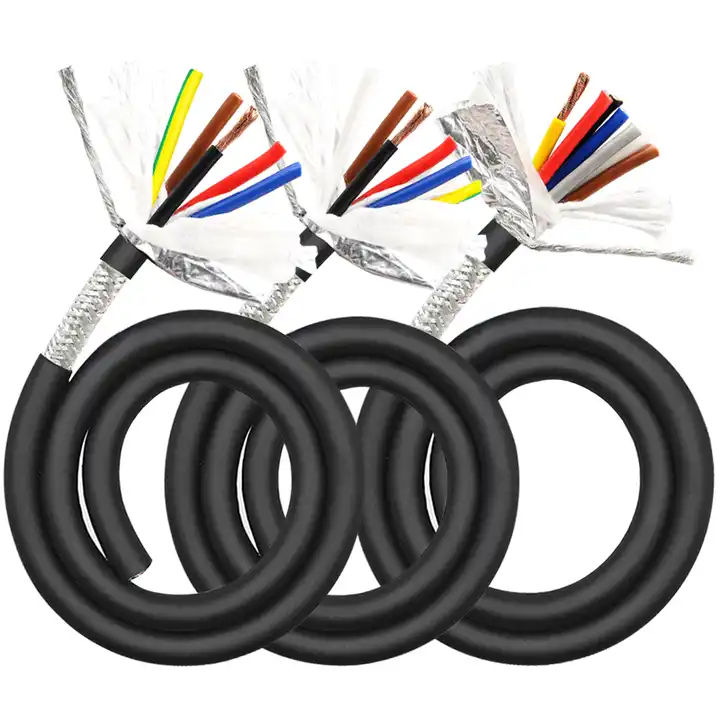

SATA hard drive data cable

Types of SATA Hard Drive Data Cables

1.Standard SATA Cables: Typically 7-pin connectors, these cables are used for general data transfer between the hard drive and motherboard.

2.SATA Power Cables: These provide the necessary power to the SATA drives and are usually 15-pin connectors.

3.eSATA Cables: Designed for external SATA drives, eSATA cables offer similar performance to internal SATA cables but with enhanced shielding and connectors for external use.

Applications in Modern Computing

1.Personal Computers and Laptops: SATA cables are widely used in desktops and laptops for connecting internal storage devices, ensuring efficient data transfer and storage management.

2.Servers and Data Centers: In server environments, SATA cables connect multiple hard drives, facilitating robust data storage solutions and ensuring quick data access and backup processes.

3.Gaming Consoles: Many gaming consoles utilize SATA cables to connect internal storage devices, enabling fast game load times and efficient data management.

4.External Storage Solutions: SATA cables are also used in external storage devices, such as external hard drives and docking stations, providing users with flexible and high-speed storage options.

Conclusion

SATA hard drive data cables play a crucial role in modern computing, offering high data transfer rates, flexible design, and hot swapping capabilities. Whether you are building a new PC, upgrading your storage, or managing a data center, understanding the importance and applications of SATA cables can help you optimize your system’s performance. Embrace the power of SATA technology and ensure your data transfer and storage needs are met with efficiency and reliability.