Recently, a sales partner encountered a difficult problem. The optical module received by the customer could not be used. After much research, the reason was found. It turned out that the customer purchased an optical module with a heat sink, which did not match the existing network card slot. What is the difference between the flat top and the heat sink top of the optical module? How to choose when using it? Let’s follow the editor to take a look!This is due to 400g aoc cable Its value attribute is relatively large, and it is easy to become the backbone of the industry. https://www.3coptics.com/

1. The difference between the flat top and the heat sink top of the optical module

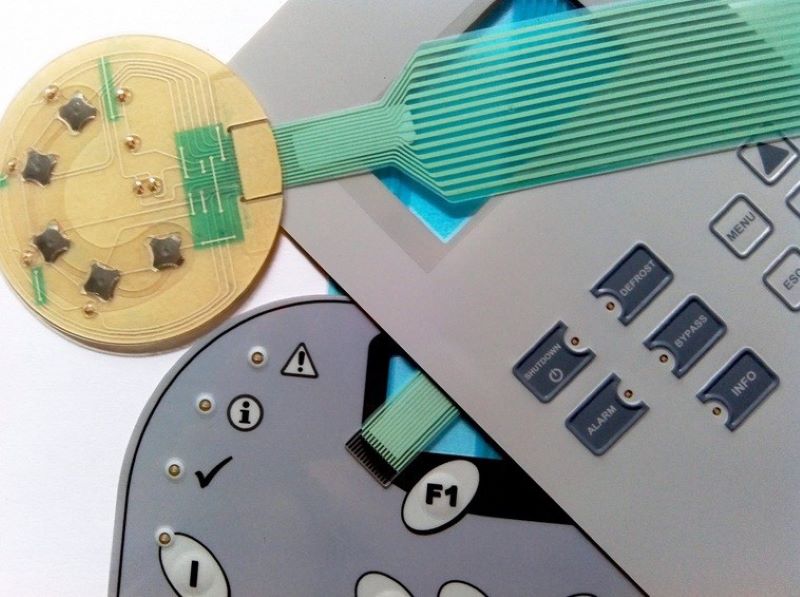

The flat top and heat sink top in the optical module usually refer to two different structures in the optoelectronic device:

Flat-top: Flat-top structure usually refers to the flat top structure of the laser or optical transmitter in the optical module. This design allows light to propagate and focus more easily, which is conducive to more efficient transmission of optical signals in optical fibers or other transmission media. The flat-top design can improve the coupling efficiency and transmission efficiency of light, and is more common in some high-performance optical communications or optical sensors.

Heatsink-top: Heatsink-top structure usually refers to the top design of laser or optoelectronic device with heat sink. These heat sinks are usually used to effectively dissipate heat to keep the device operating temperature within a safe range. In high-power or high-density applications, the device may generate a lot of heat, which needs to be transferred to the surrounding environment through the heat sink to prevent the device from overheating and damage. Therefore, the heat sink design is crucial for the long-term stable operation of the optical module.

400g optical module

2. How to choose the flat top and heat sink top of the optical module

With the increase of transmission rate, the size of the optical module is gradually miniaturized, and the requirements for internal optical devices are getting higher and higher. It is very necessary to solve the heat dissipation problem. The flat top and heat sink top of the optical module each have their advantages. Which one is better depends mainly on the transmission rate, interface type, packaging method and specific application scenarios and requirements.

Transmission distance and rate requirements: If your application requires long-distance high-speed transmission, the flat-top structure may be more suitable because it is conducive to improving the coupling efficiency and transmission efficiency of light. For short-distance or low-speed transmission, the heat sink top structure can be considered more.

Thermal management requirements: If the laser or optoelectronic device in your application needs to handle a lot of power or high-density energy, the heat sink top structure may be more important because it is conducive to effective heat dissipation, thereby maintaining the stable operation of the module and preventing overheating from causing performance degradation or damage. Especially in applications such as high-power optical communications or lidar, good thermal management is essential.

Cost and complexity: The flat-top version of the optical module has a simple design and no additional heat sink structure, because it focuses on the light transmission efficiency, while the heat sink top structure may require a more complex design and manufacturing process to ensure good heat dissipation performance. Therefore, you need to weigh these two options when considering cost and complexity.

Environmental conditions: Consider the environmental conditions in which your application will operate. If the ambient temperature is high or there may be other heat sources, good heat dissipation may be more important.

Reliability and stability requirements: If your application has high requirements for long-term stable operation of the device, it may be more appropriate to choose a heat sink top structure that can provide good thermal management.