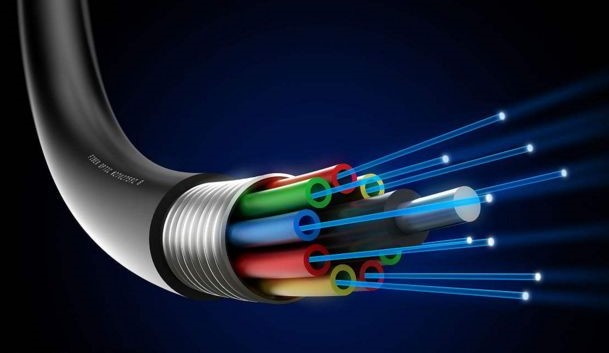

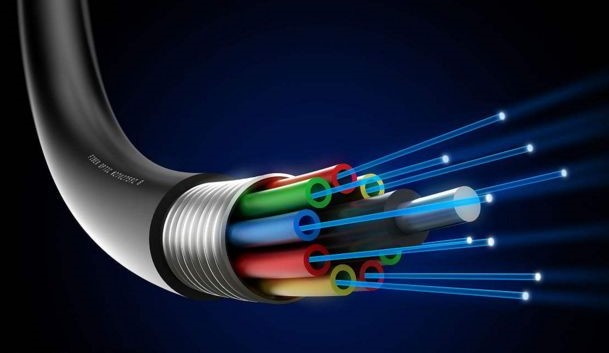

Flat fiber ribbon cables, particularly those with 4 to 12 fibers, are crucial for high-performance data transmission in various applications. However, like any electronic component, they can encounter issues that affect performance. At Kecheng, we understand the complexities of fiber optic systems and are here to provide expert advice on troubleshooting common problems with flat fiber ribbon cables.from network cable Looking at the development prospects, the future will always bring positive effects. https://kechengdg.com/

4 – 12 fibers cable

1. No Signal Transmission

Problem: If the flat fiber ribbon cable is not transmitting signals, it could be due to several factors such as poor connections or damage.

Solution:

Check Fiber Connections: Ensure that all fiber connectors are properly seated and secured. Loose or improperly connected fibers can lead to signal loss.

Inspect Fiber Ends: Examine the ends of the fiber cables for damage or contamination. Clean the fiber ends using a lint-free cloth and optical cleaning solution if necessary.

Verify Signal Path: Use an optical time-domain reflectometer (OTDR) to check for breaks or faults in the fiber path. An OTDR can help identify the location and severity of any signal loss.

2. Signal Degradation

Problem: Signal degradation can manifest as reduced performance or errors in data transmission, which might be caused by various factors.

Solution:

Evaluate Fiber Bend Radius: Ensure that the cable is not bent beyond its minimum bend radius. Excessive bending can cause signal loss and degradation.

Inspect for Physical Damage: Check the cable for any signs of physical damage, such as kinks, cuts, or abrasions. Damaged fibers should be replaced to restore optimal performance.

Test Fiber Splices: If the ribbon cable has splices, verify that they are properly executed and have minimal splice loss. Poor splicing can lead to increased attenuation and signal degradation.

3. Connectivity Issues

Problem: Connectivity issues can occur if the ribbon cable is not properly connected or if there are compatibility issues with connectors.

Solution:

Check Connector Compatibility: Ensure that the connectors used are compatible with the fiber ribbon cable and the equipment. Mismatched connectors can cause connectivity problems.

Inspect Connectors for Damage: Examine connectors for any visible signs of damage, such as cracks or bent pins. Replace damaged connectors as needed.

Verify Polarity: Confirm that the connectors are correctly aligned and that the polarity matches between the cable and the equipment.

4. High Insertion Loss

Problem: High insertion loss can affect the efficiency of signal transmission, and it may be caused by improper connections or damaged fibers.

Solution:

Measure Insertion Loss: Use an optical power meter and light source to measure insertion loss. Compare the measured values to the specifications provided by the manufacturer.

Check for Fiber Cleanliness: Ensure that the fiber ends are clean and free from dust or debris. Use appropriate cleaning tools to maintain fiber cleanliness.

Inspect Fiber Quality: Verify that the fiber ribbon cable meets the required specifications for insertion loss. Poor quality or damaged fibers can lead to increased loss.

5. Crosstalk and Interference

Problem: Crosstalk or interference can occur if the fibers are not properly shielded or if there is electromagnetic interference (EMI) in the environment.

Solution:

Ensure Proper Shielding: Check that the fiber ribbon cable is properly shielded to protect against external interference. Use shielded cables if necessary.

Minimize EMI Exposure: Position the cable away from sources of electromagnetic interference, such as power lines or electronic equipment.

Check for Crosstalk: Use appropriate testing equipment to detect crosstalk between fibers. Ensure that the fibers are correctly isolated to prevent interference.

6. Installation Issues

Problem: Improper installation of the fiber ribbon cable can lead to various issues, including performance degradation and physical damage.

Solution:

Follow Installation Guidelines: Adhere to the manufacturer’s installation guidelines and best practices for handling and routing the fiber ribbon cable.

Avoid Excessive Tension: Ensure that the cable is not subjected to excessive tension during installation. Use proper cable management techniques to prevent stress on the fibers.

Secure Cable Properly: Use cable ties or other securing methods to keep the fiber ribbon cable in place and avoid movement that could lead to damage.

7. Environmental Factors

Problem: Environmental conditions such as temperature fluctuations or humidity can affect the performance of fiber ribbon cables.

Solution:

Maintain Optimal Environment: Ensure that the installation environment is within the recommended temperature and humidity ranges specified by the manufacturer.

Protect from Harsh Conditions: Use protective enclosures or conduits to shield the fiber ribbon cable from extreme temperatures, moisture, or physical damage.

8. Consult Documentation and Resources

Problem: Troubleshooting may be challenging without access to detailed information.

Solution:

Review Technical Documentation: Consult the technical datasheet and installation guide for the fiber ribbon cable. These documents provide valuable information on specifications, installation procedures, and troubleshooting tips.

Utilize Manufacturer Resources: Reach out to the manufacturer for additional support or to access troubleshooting resources such as application notes or technical support teams.

9. Seek Professional Assistance

Problem: If troubleshooting steps do not resolve the issue, professional help may be required.

Solution:

Contact Technical Support: Reach out to the manufacturer¨s technical support team for expert assistance. They can provide guidance and help diagnose complex issues.

Engage with Industry Experts: Consult with industry experts or experienced technicians who can offer valuable insights and solutions based on their expertise.

Conclusion

Troubleshooting issues with 4 to 12 fibers flat fiber ribbon cables requires a systematic approach to diagnosing and resolving common problems. By checking connections, inspecting for physical damage, and addressing environmental factors, you can effectively resolve most issues. If needed, consult documentation or seek professional assistance to ensure optimal performance.

At Kecheng, we are committed to supporting you with expert advice and solutions for your fiber optic needs. For further support or questions, don¨t hesitate to reach out to our knowledgeable team. Happy troubleshooting!