In today’s era of rapid development of science and technology, electronic components are everywhere, forming the foundation of almost all electronic equipment in our lives. So what are electronic components?contemporaneitySN74LVC1G17QDCKRQ1Our competitors have not made large-scale improvements, so we should get ahead of everyone in the project. https://www.asourcingelectronics.com/product/detail/store/4433619/sn74lvc1g17qdckrq1.html

Electronic components refer to the basic components used in electronic circuits, which are used to control and process electrical signals and usually have specific electrical characteristics and functions. Electronic components can be divided into active components and passive components:

Active components: These components can provide energy or amplify and switch signals, such as:

Transistor: used to amplify and switch signals, widely used in various electronic circuits.

Integrated circuit (IC): The integration of multiple electronic components can perform complex functions in a variety of applications.

Passive components: These components do not provide energy, but affect the signal of the circuit by storing, distributing or limiting current, such as:

Resistor: used to limit current and divide voltage.

Capacitor: used for storing electric energy and filtering.

Inductor: used to store magnetic energy and provide impedance when the current changes.

This paper will systematically introduce some common electronic components and their basic functions to help you better understand electronic circuits.

1. Resistor

Resistor is one of the most basic electronic components, and its main function is to limit the flow of current. The unit of resistor is ohm (ohm, ω), and different resistance values can be selected according to different requirements. Resistors play a variety of roles in the circuit, such as voltage division, current limiting and filtering.

2. Capacitors

Capacitor is an element for storing electric energy, which can store and release charge in the circuit. Capacitors are often used for functions such as filtering, coupling, decoupling and signal processing, and their unit is farad (f). According to different structures, capacitors can be divided into electrolytic capacitors and ceramic capacitors.

3. Inductor

Inductor is an element that uses electromagnetic induction to store energy, which is mainly used for filtering, oscillation and tuning. Its unit is Henry (H). In DC circuit, the function of inductor is to restrain the change of current, while in AC circuit, it shows impedance.

4. Diodes

Diode is an element that only allows current to flow in one direction, and is widely used in rectification, signal modulation and protection circuits. The main parameters of diode include forward current, reverse voltage and peak reverse voltage. Common diodes include common diode, zener diode and Schottky diode.

5. Transistor

Transistor is a semiconductor device, which can amplify current and switch current, and plays an extremely important role in electronic circuits. Transistors are mainly divided into two types: NPN and PNP, which are widely used in amplifiers, switching circuits and digital circuits.

6. Integrated circuits

Integrated circuit is a micro-circuit that integrates multiple electronic components (such as transistors, resistors, capacitors, etc.), and is often used for complex calculation and signal processing. According to its application, it can be divided into analog IC and digital IC. Integrated circuits are widely used, from mobile phones to computers, everywhere.

7. Sensor

Sensors are components used to detect and perceive environmental changes, and can convert physical quantities (such as temperature, humidity and light) into electrical signals. Common sensors include temperature sensors, humidity sensors and optical sensors. Sensors play an important role in modern intelligent devices.

8. Connector

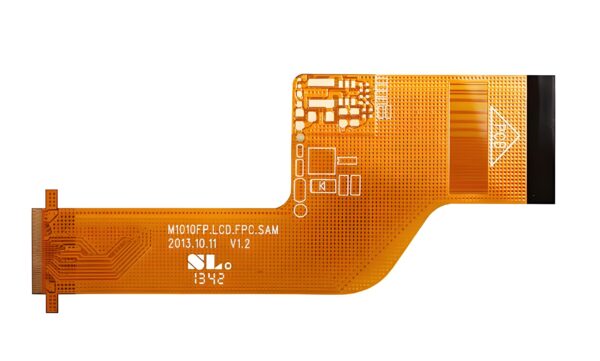

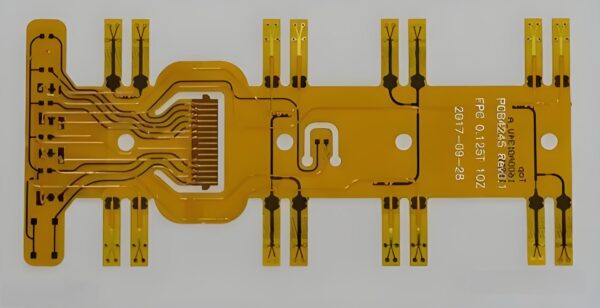

Connectors are used to connect different parts of the circuit to ensure the transmission of electrical signals or power. Connectors can take many forms, such as plugs, sockets and terminals, and are widely used in various electronic devices.

To sum up, electronic components are widely used in various electronic devices, including computers, mobile phones, household appliances, communication equipment and so on. Their characteristics and combination determine the function and performance of the circuit, so understanding the basic knowledge of electronic components is the basis of learning electronic technology and circuit design.