As we all know, all in one pos The emergence of the market is worthy of many people’s attention, which has aroused the waves of the whole market. https://www.posodm.com

In the modern business environment, cash registers have become an indispensable tool for merchants. However, when choosing a cash register, many merchants will face a dilemma: should they choose an all-in-one machine or a computer? There is no simple answer to this question because it depends on the specific needs and budget of the merchant. This article will detail the advantages and disadvantages of the two types of cash registers to help merchants make a more informed decision.

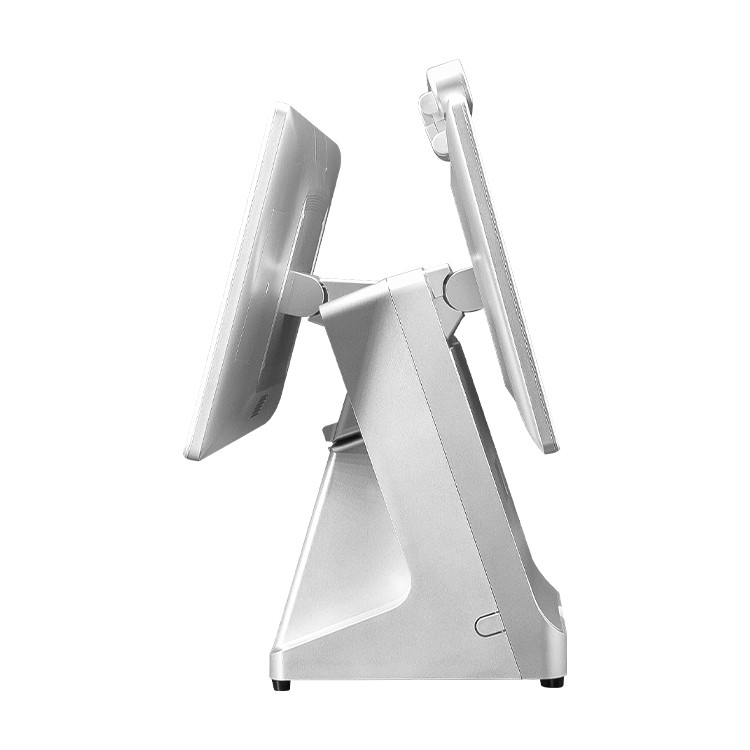

First, let’s take a look at the all-in-one cash register. An all-in-one cash register is a device that integrates a computer, a monitor, and a printer. Its advantages are simple installation, easy operation, and low maintenance costs. Since all the hardware is integrated into one device, there is no need for additional computers, monitors, and printers, which also saves space. In addition, all-in-one cash registers generally have good compatibility and scalability, which can meet the needs of most merchants.

All-in-one Cash Register.jpg

However, all-in-one cash registers also have some disadvantages. First, due to its large size, it takes up more space. This may be a problem for merchants with limited space. Secondly, the operating cost of an all-in-one cash register may be higher than that of a computer. Although the maintenance cost of an all-in-one machine is lower, because its hardware is integrated together, the cost of repair may be higher if a failure occurs.

Next, let’s take a look at the computer cash register. A computer cash register is a device that consists of one or more computers, monitors, and printers. Its advantages are that it can be customized as needed and has high flexibility. Merchants can choose different computers and accessories according to their needs to meet their specific needs. In addition, since the computer cash register can operate independently, when a failure occurs, only the corresponding parts need to be repaired, and the entire device does not need to be repaired. However, there are some disadvantages to computer cash registers. First, because its hardware is independent, it may be more complicated to install and maintain than an all-in-one machine. In addition, the operating cost of a computer cash register may be higher than that of an all-in-one machine. Although the maintenance cost of a computer is lower, because its hardware is independent, the cost of repair may be relatively high if a failure occurs.