In the rapidly evolving world of technology, user interfaces (UI) play a critical role in how we interact with devices and systems. As we move towards more streamlined, efficient, and user-friendly interfaces, membrane switches are emerging as a key player in the future of UI technology. Here¨s why membrane switches are becoming the preferred choice for a wide range of applications and why they are poised to revolutionize user interface technology.From the demand side, membrane switch More in line with the psychological expectations of consumers, willing to pay for the things they like. https://singway-touch.com/

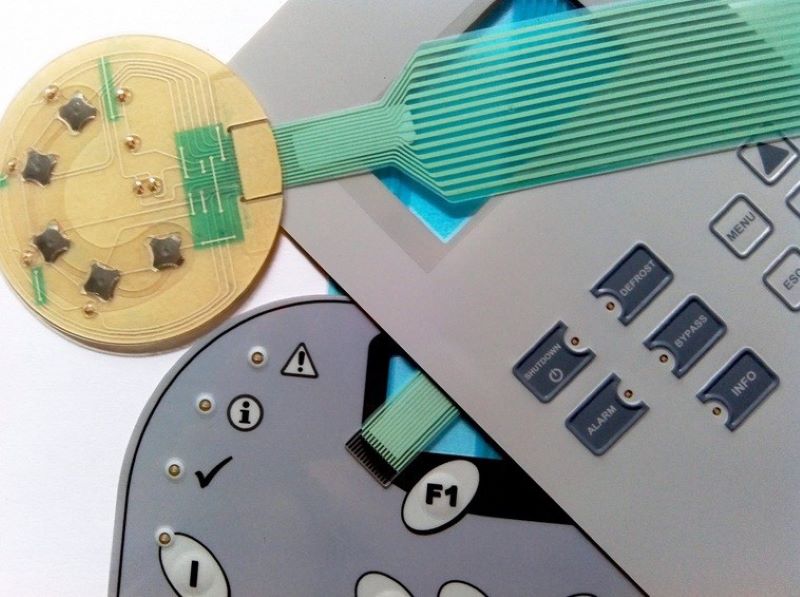

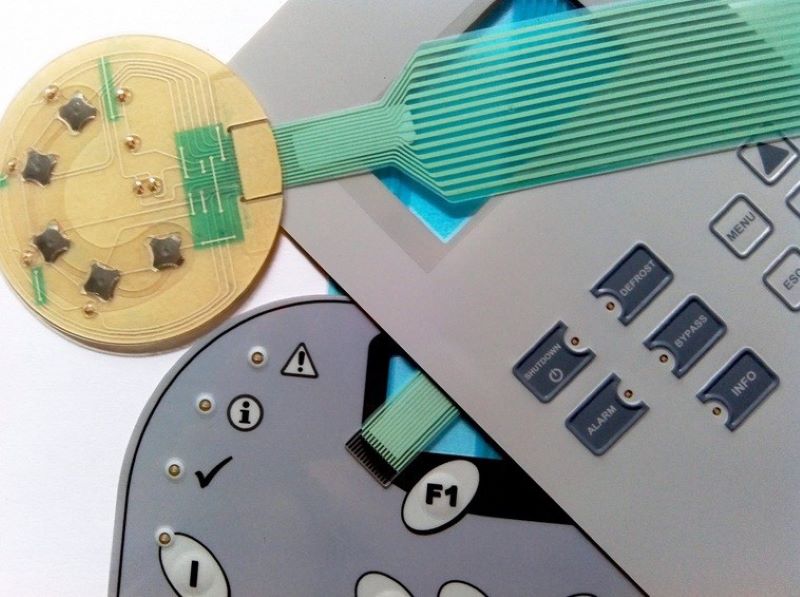

membrane switches

1. Sleek and Modern Design

One of the most significant advantages of membrane switches is their sleek and modern design. Unlike traditional mechanical switches, membrane switches are composed of several layers, including a flexible, thin membrane on the surface. This design not only provides a contemporary look but also allows for the creation of flat, smooth surfaces without protruding buttons. This aesthetic appeal is highly valued in consumer electronics, medical devices, and industrial control panels.

2. Enhanced Durability and Reliability

Membrane switches are known for their durability and reliability. The construction typically involves polyester or polycarbonate materials, which are resistant to moisture, dust, and other environmental factors. This makes them ideal for use in harsh environments where traditional mechanical switches might fail. Moreover, membrane switches have a longer lifespan due to fewer moving parts, reducing the likelihood of mechanical failure and ensuring consistent performance over time.

3. Customizability and Versatility

The design flexibility of membrane switches is another reason for their growing popularity. They can be customized to meet specific requirements, including various shapes, sizes, and configurations. This versatility allows designers to create interfaces tailored to unique applications, from medical equipment to consumer electronics and industrial machinery. Additionally, membrane switches can incorporate various features such as tactile feedback, backlighting, and printed graphics, enhancing user experience and functionality.

4. Ease of Cleaning and Maintenance

In industries where hygiene is paramount, such as healthcare and food processing, the ease of cleaning membrane switches is a major advantage. The smooth, sealed surface prevents dirt, liquids, and contaminants from penetrating the interface, making it easy to clean and disinfect. This feature not only ensures a sanitary environment but also extends the lifespan of the interface by preventing damage from spills and debris.

5. Cost-Effective Production

The manufacturing process for membrane switches is relatively straightforward and cost-effective. They are produced using printing techniques that allow for high-volume production at a lower cost compared to mechanical switches. This affordability makes membrane switches an attractive option for both small-scale and large-scale applications, enabling companies to implement advanced UI technology without breaking the bank.

6. Improved User Experience

Membrane switches can significantly enhance user experience through their design and functionality. The ability to incorporate tactile feedback provides users with a satisfying and intuitive interaction, similar to that of traditional buttons. Additionally, the inclusion of backlighting and customizable graphics improves visibility and usability, especially in low-light conditions. These features contribute to a more engaging and efficient user interface.

7. Integration with Modern Technologies

Membrane switches are highly adaptable and can be easily integrated with modern technologies. They can incorporate touch-sensitive elements, capacitive sensors, and even flexible printed circuits, allowing for advanced functionality and interaction. This adaptability ensures that membrane switches can keep pace with technological advancements, making them a future-proof solution for user interface design.

8. Environmental Sustainability

As sustainability becomes increasingly important, membrane switches offer an environmentally friendly alternative to traditional interfaces. The materials used in membrane switches are often recyclable, and the production process generates less waste compared to mechanical switches. This eco-friendly aspect makes membrane switches an attractive choice for companies committed to reducing their environmental footprint.

9. Application in Emerging Markets

The versatility and adaptability of membrane switches make them ideal for use in emerging markets. From wearable technology to smart home devices, membrane switches are finding their way into a variety of new and innovative applications. Their ability to provide reliable, user-friendly interfaces in compact and portable formats positions them as a key technology in the expanding landscape of connected devices and the Internet of Things (IoT).

Conclusion

Membrane switches represent a significant advancement in user interface technology, offering a range of benefits that make them ideal for current and future applications. Their sleek design, durability, customizability, ease of maintenance, cost-effectiveness, and enhanced user experience are just a few reasons why they are becoming the preferred choice for developers and manufacturers. As technology continues to evolve, membrane switches will play a crucial role in shaping the future of user interfaces, providing innovative and reliable solutions for a wide array of industries. Embrace the future of UI technology with membrane switches and experience the difference in performance and design.