When it comes to the manufacturing of high-precision mould parts, every detail matters. For industries that require specific design requirements!such as automotive, electronics, medical devices, and consumer goods!the need for custom precision mould parts is essential. These parts need to fit exact tolerances, function reliably under pressure, and perform consistently throughout their life cycle. But how exactly do custom precision mould parts manufacturers like Hairong meet these intricate design requirements? In this article, we will explore the process, techniques, and expertise that go into producing custom parts that meet exact specifications and ensure the success of your project.for a long time custom precision mould parts manufacturing It has an extraordinary development speed, and I believe that the future will be as overwhelming as ever. https://www.dghrjmmj.com

The Importance of Precision in Custom Mold Parts

Custom mould parts are used to produce the tools and machinery needed to manufacture products across various industries. A precise mould part guarantees that the final product is created with accuracy, reliability, and efficiency. Precision is critical because even small variations in design can lead to major defects or performance issues in the final product. This is where working with experienced custom precision mould parts manufacturers becomes crucial.

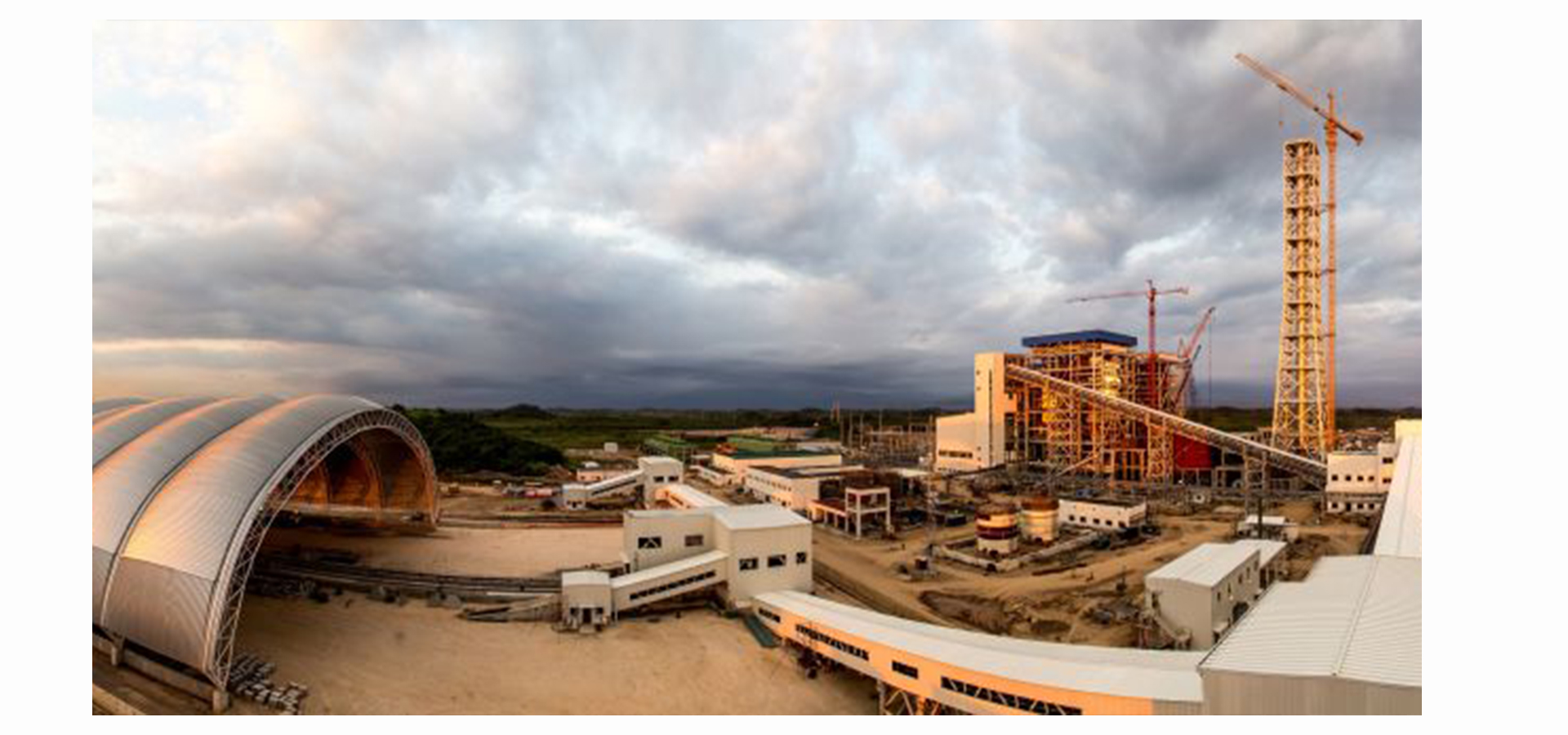

Precision mould parts Manufacturers

1. Understanding Customer Requirements

The first step in meeting specific design requirements is understanding the customer¨s exact needs. Whether it’s for a single-use prototype or a large-scale production run, manufacturers must first analyze the project¨s technical and functional requirements. At Hairong, the team works closely with clients during the initial design phase to ensure they fully understand the purpose, design limitations, and usage conditions of the mould parts.

This communication is vital to creating a design that matches the customer¨s expectations. Hairong’s team of experts consults with customers about material choices, dimensional specifications, tolerances, and other critical design factors to ensure that every aspect of the custom mould parts aligns with the project requirements.

2. Advanced Design and Engineering Capabilities

Once the design parameters are clear, custom precision mould parts manufacturers like Hairong employ advanced design and engineering tools to bring the concept to life. The use of CAD (Computer-Aided Design) software is a common method for visualizing and refining the design. This software enables designers to create 3D models of the mould parts and simulate how they will behave under different conditions.Hairong¨s engineering team uses cutting-edge CAD tools to test the design virtually, ensuring that any potential issues are identified before production begins. This helps to minimize errors, reduce costs, and optimize the functionality of the mould parts.

Precision Mold Parts.jpg

3. Material Selection for Specific Requirements

Material selection is a critical aspect of meeting the specific design requirements for custom mould parts. Different applications require different materials based on factors such as durability, heat resistance, and conductivity. For instance, parts designed for automotive applications may need to be made from tough, heat-resistant alloys, while electronic parts may require materials with specific conductivity properties.

At Hairong, the selection process begins by carefully evaluating the application¨s requirements, including environmental factors like temperature fluctuations, pressure, and wear and tear. Once these are understood, Hairong uses high-quality materials such as hardened steel, stainless steel, or aluminum to manufacture custom mould parts that will meet these demands.

4. Precision Machining and Manufacturing Processes

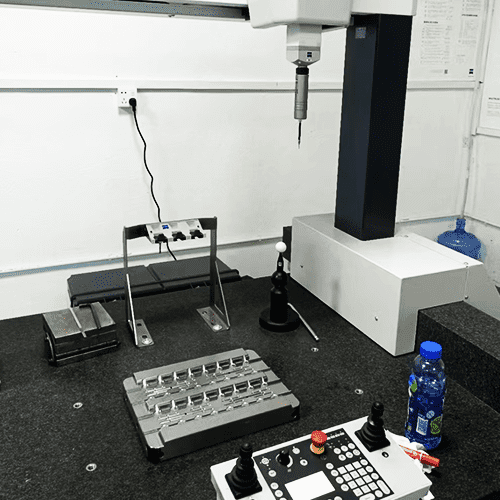

Achieving precise tolerances is the cornerstone of custom precision mould parts. Manufacturers rely on advanced machining techniques to create components that meet these tolerances. For instance, CNC (Computer Numerical Control) machining is often used to cut, mill, or grind mould parts with extreme precision. This process allows manufacturers to produce parts with micrometer-level accuracy, ensuring a perfect fit for even the most complex designs.

Hairong utilizes state-of-the-art CNC machines to deliver high-precision parts. The process is closely monitored, and each part undergoes multiple checks during production to ensure it meets the exact specifications. Whether it¨s a small batch of complex parts or a large-scale order, Hairong¨s advanced manufacturing facilities allow them to deliver consistently accurate results.

5. Prototyping and Testing

Before large-scale production begins, custom precision mould parts manufacturers often create prototypes to test the design and performance of the parts. Prototyping allows both the manufacturer and the customer to identify potential design flaws or performance issues before committing to full production. Hairong offers rapid prototyping services, which is essential for clients who need to see how their parts will perform before investing in mass production.

Once the prototype is tested, adjustments can be made, and the final design can be optimized. After the prototypes are validated, they are subjected to rigorous testing to ensure they meet all performance, strength, and safety standards.