In recent years, Custom HD COB LED Displays have emerged as a cutting-edge solution for industries seeking high-definition visuals with versatility. Featuring Chip-on-Board (COB) technology, these displays offer seamless visuals, exceptional durability, and unparalleled flexibility, making them the go-to choice for a wide range of applications.more importantly, led screen manufacturer Made a fighter in the product, not afraid of any competitor’s attack. https://www.dkingdisplay.com/

What Are Custom HD COB LED Displays?

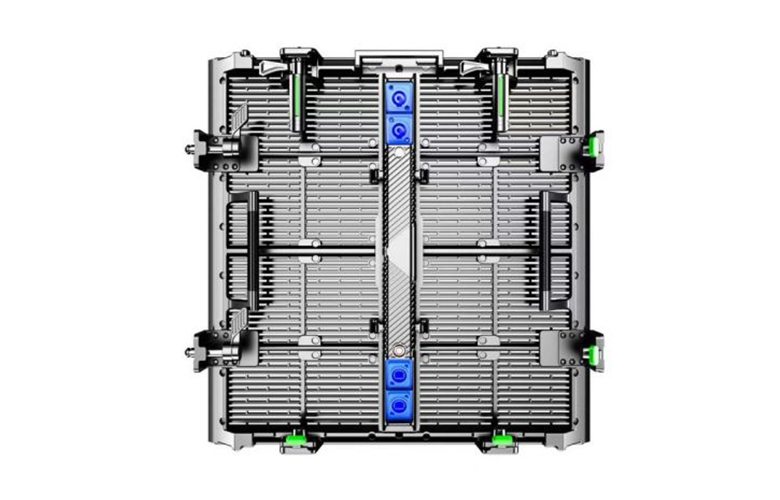

Custom HD COB LED Displays utilize advanced COB technology, where multiple LED chips are directly bonded onto a substrate, eliminating the need for individual packaging. This creates a compact, robust design that delivers:

Higher pixel density for sharp visuals.

Enhanced durability due to better heat dissipation.

Customizable designs to fit unique project requirements.

Their compact form factor and high reliability make them ideal for creating tailored visual solutions across industries.

Key Applications of Custom HD COB LED Displays

1. Retail and Advertising

Retailers and advertisers leverage these displays for eye-catching digital signage. Their superior brightness and vivid colors ensure messages stand out in crowded environments. Custom HD COB LED Display can be tailored to fit unconventional shapes and sizes, enabling creative and immersive advertising campaigns.

2. Corporate Environments

Boardrooms and conference halls benefit from these displays¨ high resolution and seamless design. Customization allows for integration into existing infrastructure, enhancing presentations and collaborative workspaces.

3. Broadcast and Media

COB technology¨s high contrast and minimal reflection make these displays ideal for broadcast studios. Custom HD COB LED Display deliver lifelike visuals, ensuring on-camera clarity even under intense lighting.

4. Entertainment and Events

From concerts to exhibitions, event organizers utilize custom LED screens for dynamic stage backdrops and immersive experiences. Their flexibility allows for creative setups like curved screens or interactive designs, capturing audience attention.

5. Healthcare and Education

Hospitals use these displays for high-precision imaging in diagnostic tools, while educational institutions integrate them into smart classrooms for interactive learning. Customization ensures they meet specific size and resolution requirements.

6. Transportation Hubs

Airports and train stations use Custom HD COB LED Display for real-time passenger information. Their durability ensures they withstand constant use, while high visibility ensures clear communication in busy areas.

Benefits of Custom HD COB LED Displays

Tailored to Fit

Unlike standard displays, these can be customized to specific dimensions, resolutions, and shapes, meeting unique project requirements.

Durability

COB technology ensures the displays are resistant to damage from dust, water, and physical impact, making them suitable for demanding environments.

Seamless Visuals

The lack of visible gaps between modules results in a smooth, uninterrupted display, perfect for large-scale visuals.

Energy Efficiency

Custom HD COB LED Display consume less power compared to older display technologies, reducing operating costs over time.

Long Lifespan

The robust construction of COB technology extends the life of these displays, ensuring a reliable investment for businesses.