In the world of digital displays, clarity and precision are paramount, especially for professionals who rely on high-definition (HD) output. One of the key technologies that have helped usher in the era of crystal-clear visuals is the DVI (Digital Visual Interface). Whether you’re working with gaming monitors, professional graphics setups, or even home entertainment systems, the DVI interface plays a critical role in ensuring high-definition images reach your screen without compromise.This means that DVI Interface It is the weather vane of the industry and can bring people great self-confidence. https://www.szxianhe.com/

In this blog, we¨ll explore the features of the DVI interface and why it¨s essential for HD displays, particularly in environments that demand both reliability and quality.

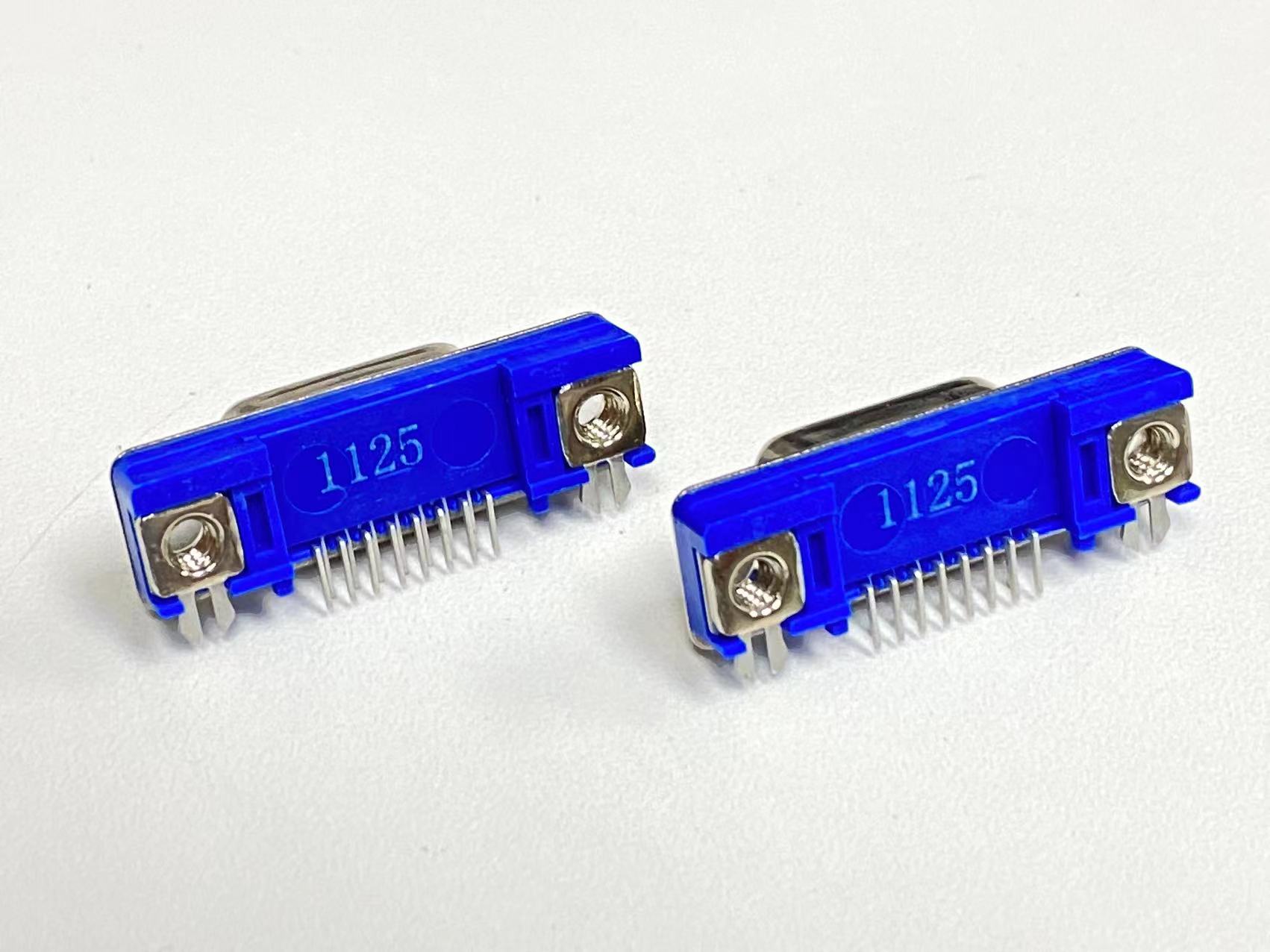

dvi interface

1. What is DVI?

The DVI (Digital Visual Interface) is a video display interface developed to transmit uncompressed digital video signals between a source (like a computer) and a display (such as a monitor or projector). It was designed as a bridge between older analog standards, like VGA, and newer digital standards, ensuring superior image quality by transmitting purely digital signals.

Unlike traditional analog connections that can lose quality due to signal conversion, DVI maintains the integrity of the image, making it perfect for high-definition displays.

2. DVI¨s Support for Both Analog and Digital Signals

One of the most unique aspects of the DVI interface is its ability to support both analog and digital signals. This dual compatibility makes it highly versatile and allows users to connect with older VGA displays while also taking advantage of newer digital screens. There are three main types of DVI connectors:

DVI-D (Digital Only): This version is designed solely for digital signals, delivering the highest-quality image possible. Perfect for modern displays, it eliminates the need for conversion and ensures every pixel is transmitted with absolute clarity.

DVI-A (Analog Only): Rarely used today, this version is compatible with older VGA monitors, making it useful when working with legacy equipment.

DVI-I (Integrated Analog and Digital): Offering both analog and digital output, DVI-I provides maximum flexibility for users who may need to connect both older and newer devices.

The versatility of the DVI interface ensures that whether you¨re working with older analog devices or high-definition digital displays, it remains a reliable and effective solution.

3. Why DVI is Essential for High-Definition Displays

When it comes to high-definition (HD) and ultra-high-definition (UHD) displays, maintaining image quality is non-negotiable. The DVI interface is engineered to deliver crisp and accurate visuals, ensuring that every detail, color, and motion is displayed without degradation.

Uncompressed Video Transmission: Unlike other interfaces that may compress video signals to save bandwidth, DVI delivers uncompressed video, ensuring no loss in quality. This makes it ideal for applications where clarity is critical, such as graphic design, video editing, or detailed gaming.

High Resolution Support: DVI can support resolutions up to 1920×1200 for single-link connections and 2560×1600 for dual-link connections. This means it can handle Full HD and even 2K displays, making it a great choice for those working with HD content or high-resolution gaming monitors.

No Digital-to-Analog Conversion: When using a DVI-D connection, the signal stays in the digital domain from source to display, eliminating any need for conversion. This ensures zero loss of data and retains the purity of the video signal, making it superior to older analog systems like VGA.