What Are the Future Trends in Precision Manufacturing Services

The above conclusions show that precision plastic mould components To a great extent, it can bring new vitality to the market and make the industry develop well. https://www.dghrjmmj.com

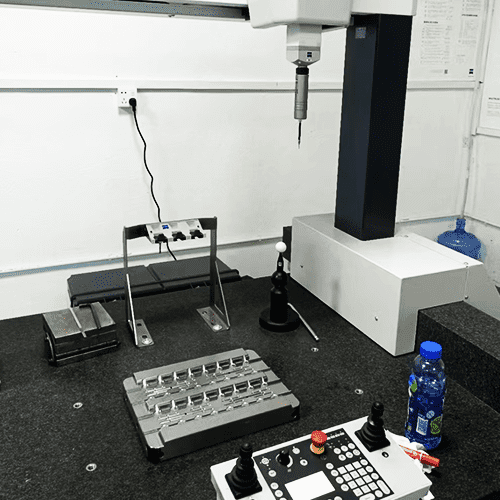

In the rapidly evolving world of manufacturing, precision manufacturing services are at the forefront of innovation and technological advancement. These services are essential for producing high-quality components that meet stringent specifications across various industries, including aerospace, automotive, medical devices, and electronics. As we look to the future, several trends are poised to shape the landscape of precision manufacturing services, high precision machining services, and the role of mold core pins manufacturers.

high quality precision mould parts supplier.jpg

1. Integration of Smart Manufacturing Technologies

One of the most significant trends in precision manufacturing services is the integration of smart manufacturing technologies. The Industrial Internet of Things (IIoT), artificial intelligence (AI), and machine learning are being increasingly utilized to enhance production efficiency, quality control, and predictive maintenance. These technologies enable manufacturers to collect and analyze vast amounts of data in real-time, allowing for more informed decision-making and reducing downtime.For instance, AI-driven analytics can predict equipment failures before they occur, ensuring continuous operation and minimizing costly interruptions. This trend is particularly relevant for high precision machining services, where even minor disruptions can lead to significant delays and increased production costs.

2. Advanced Materials and Processes

The development of advanced materials and processes is another trend that will continue to impact precision manufacturing services. Materials such as carbon fiber composites, advanced ceramics, and high-performance alloys are increasingly being used to create components with superior strength-to-weight ratios, durability, and resistance to extreme environments.

Moreover, new manufacturing processes like additive manufacturing (3D printing) and advanced machining techniques are enabling the production of complex geometries that were previously impossible or cost-prohibitive. High precision machining services are now capable of achieving tighter tolerances and more intricate designs, meeting the ever-increasing demands of industries like aerospace and medical devices.

customized precision mould parts.jpg

3. Customization and Flexibility

As consumer demands become more personalized, manufacturers are under pressure to provide customization without sacrificing efficiency or quality. This trend is driving the adoption of flexible manufacturing systems that can quickly adapt to produce a wide variety of products.Precision manufacturing services are leveraging modular equipment and reconfigurable production lines to offer greater customization options. This flexibility is crucial for mold core pins manufacturers who must produce highly specialized components tailored to specific applications. The ability to quickly switch between different production setups allows these manufacturers to meet diverse customer requirements while maintaining high standards of precision and quality.

4. Sustainability and Green Manufacturing Practices

Sustainability is an increasingly important consideration for manufacturers worldwide. Precision manufacturing services are no exception, as companies strive to reduce their environmental impact through green manufacturing practices. This includes minimizing waste, reducing energy consumption, and utilizing eco-friendly materials.High precision machining services are adopting sustainable practices by implementing energy-efficient machinery, recycling metal shavings and cutting fluids, and optimizing production processes to minimize waste. Mold core pins manufacturers are also exploring sustainable materials and coatings that extend the lifespan of their products while reducing environmental harm.

5. Globalization and Supply Chain Resilience

The globalization of supply chains has brought both opportunities and challenges to precision manufacturing services. While access to international markets has expanded, recent disruptions have highlighted the need for resilient supply chains. Manufacturers are investing in strategies to mitigate risks associated with global supply chain dependencies.This includes diversifying suppliers, increasing local production capabilities, and utilizing digital supply chain management tools. For high precision machining services and mold core pins manufacturers, ensuring a reliable supply chain is critical to maintaining consistent quality and meeting delivery deadlines.